Applications

1. Aerospace and Transportation

Locations:

Aircraft hangars: Aircraft maintenance may result in fuel vapor leaks (jet fuel) or the presence of flammable cleaning agents.

Ship compartments (cargo holds, engine rooms): Ships, especially those transporting chemicals or fuel, may experience the accumulation of flammable vapors.

Automobile paint booths: Flammable paints and thinners are used, and their vapors are explosive when mixed with air.

Highway tunnels: Tunnels can become hazardous areas if a vehicle transporting hazardous chemicals leaks, so explosion-proof lighting is a safety standard.

2. Military and Fireworks Industry

Locations: Gunpowder, explosives, and detonator production and storage workshops; fireworks manufacturing plants.

Risks: These locations are inherently filled with flammable and explosive materials, and any electrical spark could potentially cause a disaster. Therefore, the explosion-proof requirements for electrical equipment are extremely high.

3. Laboratories and Research Institutions

Locations: Chemical and biological laboratories (which may use flammable solvents such as hydrogen).

Risks: During experiments, flammable gases, vapors, or dusts may be used or generated, necessitating the use of explosion-proof lighting and electrical appliances, either in small areas or throughout the entire laboratory.

4. Special Commercial Locations

Locations: Printing plants and dry cleaners (which utilize traditional flammable solvents such as tetrachloroethylene) that use large quantities of alcohol-based disinfectants or solvents.

Risks: While not directly industrial environments, the concentrations of flammable vapors generated during work may reach dangerous levels.

How do I determine whether I need explosion-proof lighting?

Simply put, if a location is classified as an "explosive atmosphere" and has been clearly divided into explosion-hazardous zones (e.g., Zone 0, Zone 1, Zone 2; Zone 20, Zone 21, Zone 22) according to national standards (such as China's GB3836), then all electrical equipment within that area, including lighting, must use explosion-proof products of the corresponding explosion-proof grade and type.

Key keywords: flammable gases, flammable vapors, combustible dusts, and flammable fibers. Whenever these substances may be present in the work environment, the use of explosion-proof electrical equipment must be prioritized to ensure the safety of life and property.

The Importance of Using Explosion-Proof Products

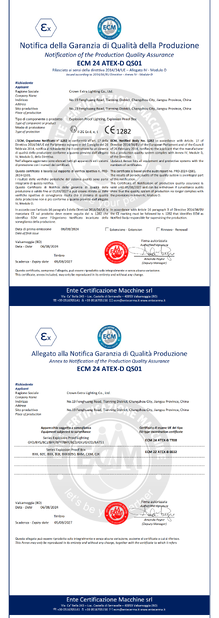

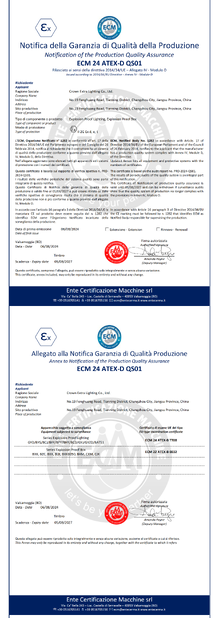

1. Complying with International Regulations and Avoiding Legal Risks

Strict Global Regulation:

EU: The ATEX Directive (2014/34/EU) mandates the use of explosion-proof equipment in high-risk areas. USA: NEC (National Electrical Code) 500-506 Zone Divisions, OSHA regulated.

China: GB 3836-2010 Explosion-Proof Standards, Coal Mine Safety Regulations (AQ Standards).

Violation Penalties: Companies that fail to use compliant explosion-proof products may face heavy fines, production suspensions, and even criminal prosecution.

2. Improve Production Efficiency and Reduce Maintenance Costs

Explosion-proof LED Luminaires: Save 60% more energy than traditional explosion-proof metal halide lamps, with a lifespan of up to 50,000 hours, reducing replacement frequency.

Intelligent Explosion-Proof Systems: Integrated sensors and remote monitoring improve safety management efficiency.

Reduced Maintenance Downtime: Explosion-proof products are corrosion-resistant and vibration-resistant, suitable for harsh environments and reducing failure rates.

3. Adapt to Extreme Environments, Ensure Reliable Operation

Explosion-proof products are designed for harsh operating conditions and feature:

High/Low Temperature Resistance (-60°C to +80°C, suitable for Arctic oil fields or desert refineries).

Waterproof and Dustproof (IP66/IP68, suitable for offshore platforms or wet mines). Corrosion-resistant (316 stainless steel or special coating to resist chemical corrosive gases).

Technical Parameters

| Type |

Plug & Receptacle |

| Ex Rate |

Ex d e IIC T6 Gb |

| Rated Current【A】 |

16 |

32 |

63 |

| Rated Voltage |

220/380VAC |

|

Degree of protection

|

IP66 |

| Entries |

M25*1.5 (suitable for

Φ8mm-Φ17mm cable)

|

M40*1.5 (suitable for

Φ13mm-Φ27mm cable)

|

M40*1.5 (suitable for

Φ13mm-Φ27mm cable)

|

| The cable for plug |

Φ8mm-Φ19mm |

Φ12mm-Φ28mm |

Φ12mm-Φ28mm |

Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten!

Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten! Bitte überprüfen Sie Ihre E-Mail!

Bitte überprüfen Sie Ihre E-Mail!  Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten!

Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten! Bitte überprüfen Sie Ihre E-Mail!

Bitte überprüfen Sie Ihre E-Mail!