Anwendungen

1. Erdöl- und chemische Industrie

Standorte: Raffinerien, Chemiewerke, Bohrplattformen, Tankstellen und Öldepots.

Gefährliche Stoffe: Entzündliche und explosive Gase und Dämpfe wie Rohöl, Erdgas, Benzin, Benzol und Alkohole.

2. Kohlebergbau

Standorte: Unterirdische Tunnel, Abbaustrecken und Übergabestationen.

Gefährliche Stoffe: Gas (hauptsächlich Methan) und Kohlenstaub.

3. Staubexplosionsatmosphären

Standorte: Getreidemühlen, Zuckerfabriken, Futtermittelwerke, Metallverarbeitungsbetriebe (Aluminium- und Magnesiumpulver), Holzverarbeitungsbetriebe und Kunststoffwerke.

Gefährliche Stoffe: Brennbarer Staub, der in der Luft schwebt.

4. Pharma- und Lebensmittelindustrie

Standorte: Einige Rohstoffwerkstätten, Ethanolextraktionsanlagen und Bereiche zur Verarbeitung von Stärke- oder Zuckerpulver.

Gefährliche Stoffe: Alkoholdämpfe und brennbarer Staub.

5. Andere Industriestandorte

Standorte: Lackieranlagen (Lösungsmitteldämpfe), Lösungsmittellager, Gaskesselräume und Kläranlagen (können Methan erzeugen).

Gefährliche Stoffe: Verschiedene brennbare und explosive Chemikalien.

Wie bestimme ich, ob ich explosionsgeschützte Beleuchtung benötige?

Einfach ausgedrückt: Wenn ein Standort als "explosionsgefährdete Atmosphäre" eingestuft wurde und gemäß nationalen Standards (z. B. Chinas GB3836) eindeutig in explosionsgefährdete Zonen unterteilt wurde (z. B. Zone 0, Zone 1, Zone 2; Zone 20, Zone 21, Zone 22), dann müssen alle elektrischen Geräte in diesem Bereich, einschließlich der Beleuchtung, explosionsgeschützte Produkte der entsprechenden Explosionsschutzklasse und -art verwenden.

Schlüsselwörter: brennbare Gase, brennbare Dämpfe, brennbare Stäube und brennbare Fasern. Wenn diese Stoffe in der Arbeitsumgebung vorhanden sein können, muss die Verwendung von explosionsgeschützten elektrischen Geräten priorisiert werden, um die Sicherheit von Leben und Eigentum zu gewährleisten.

Die Bedeutung der Verwendung von explosionsgeschützten Produkten

1. Einhaltung internationaler Vorschriften und Vermeidung rechtlicher Risiken

Strenge globale Regulierung:

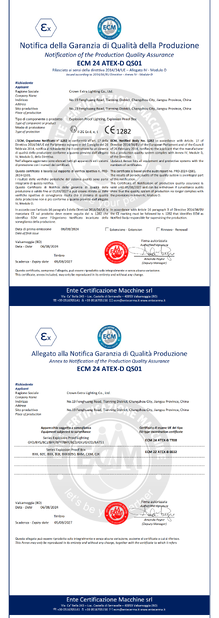

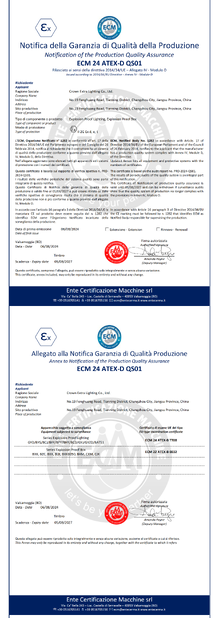

EU: Die ATEX-Richtlinie (2014/34/EU) schreibt die Verwendung von explosionsgeschützten Geräten in Bereichen mit hohem Risiko vor. USA: NEC (National Electrical Code) 500-506 Zoneneinteilungen, OSHA-reguliert.

China: GB 3836-2010 Explosionsschutzstandards, Arbeitssicherheitsvorschriften für Kohlebergwerke (AQ-Standards).

Verstoßstrafen: Unternehmen, die keine konformen explosionsgeschützten Produkte verwenden, können mit hohen Geldstrafen, Produktionsunterbrechungen und sogar strafrechtlicher Verfolgung rechnen.

2. Verbesserung der Produktionseffizienz und Reduzierung der Wartungskosten

Explosionsgeschützte LED-Leuchten: Sparen 60 % mehr Energie als herkömmliche explosionsgeschützte Metallhalogenidlampen, mit einer Lebensdauer von bis zu 50.000 Stunden, wodurch die Austauschhäufigkeit reduziert wird.

Intelligente explosionsgeschützte Systeme: Integrierte Sensoren und Fernüberwachung verbessern die Effizienz des Sicherheitsmanagements.

Reduzierte Wartungsausfallzeiten: Explosionsgeschützte Produkte sind korrosionsbeständig und vibrationsfest, geeignet für raue Umgebungen und reduzieren die Ausfallraten.

3. Anpassung an extreme Umgebungen, Gewährleistung eines zuverlässigen Betriebs

Explosionsgeschützte Produkte sind für raue Betriebsbedingungen ausgelegt und verfügen über:

Hoch-/Tieftemperaturbeständigkeit (-60 °C bis +80 °C, geeignet für arktische Ölfelder oder Wüstenraffinerien).

Wasser- und Staubdichtigkeit (IP66/IP68, geeignet für Offshore-Plattformen oder nasse Bergwerke). Korrosionsbeständig (Edelstahl 316 oder Spezialbeschichtung zur Beständigkeit gegen chemische korrosive Gase).

Technische Parameter

| Typ |

Stecker & Buchse |

| Ex-Rate |

Ex d e IIC T6 Gb |

| Nennstrom[A] |

16 |

32 |

63 |

| Nennspannung |

220/380VAC |

|

Schutzart

|

IP66 |

| Einführungen |

M25*1.5 (geeignet für

Φ8mm-Φ17mm Kabel)

|

M40*1.5 (geeignet für

Φ13mm-Φ27mm Kabel)

|

M40*1.5 (geeignet für

Φ13mm-Φ27mm Kabel)

|

| Das Kabel für den Stecker |

Φ8mm-Φ19mm |

Φ12mm-Φ28mm |

Φ12mm-Φ28mm |

Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten!

Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten! Bitte überprüfen Sie Ihre E-Mail!

Bitte überprüfen Sie Ihre E-Mail!  Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten!

Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten! Bitte überprüfen Sie Ihre E-Mail!

Bitte überprüfen Sie Ihre E-Mail!