Beschreibung des Produkts:

Die Ex Proof Cable Gland ist eine hochwertige, zuverlässige Lösung, die die sichere Verbindung von Kabeln in gefährlichen Umgebungen gewährleistet.Genau konstruiert und mit hochwertigen Materialien gefertigt, ist diese Kabeldrüse speziell für die Einhaltung strenger Sicherheitsstandards entwickelt worden, was sie zu einer idealen Wahl für Industriezweige macht, in denen explosions- und flammdichte Ausrüstung obligatorisch ist.Mit seiner robusten Konstruktion und überlegenen Dichtungsfähigkeiten, garantiert die Ex Proof Cable Gland Schutz vor Wasser, Staub und Sprenggasen, was die Integrität und Langlebigkeit Ihrer elektrischen Anlagen gewährleistet.

Eine der Hauptmerkmale des Ex Proof Cable Gland ist seine Kompatibilität mit einer Vielzahl von Kabeldurchmessern.mit einer Breite von mehr als 20 mm,Diese Flexibilität macht es vielseitig und bequem für verschiedene Anwendungen, so dass es nahtlos mit verschiedenen Kabeltypen und -größen integriert werden kann, ohne die Sicherheit oder Leistung zu beeinträchtigen.

Die Ex Proof Cable Gland ist aus hochwertigem Messing und Gummi gefertigt und bietet eine außergewöhnliche Haltbarkeit und Widerstandsfähigkeit gegen raue Umweltbedingungen.Das Messingmaterial bietet eine hervorragende mechanische Festigkeit und KorrosionsbeständigkeitDie Gummibauteile sorgen für eine dichte, wasserdichte Dichtung um das Kabel,Verhinderung des Eintritts von Feuchtigkeit und Verunreinigungen in das GehäuseDies macht die Drüse nicht nur explosionssicher, sondern auch eine wirksame wasserdichte Kabeldüse, die Ihre Geräte vor Wasserschäden schützt und einen kontinuierlichen Betrieb gewährleistet.

Die silberne Oberfläche des Ex Proof Cable Gland verbessert nicht nur seine ästhetische Anziehungskraft, sondern trägt auch zu seiner Korrosionsbeständigkeit bei.mit einer Breite von mehr als 20 mm,, einschließlich chemischer Anlagen, Ölraffinerien und Offshore-Anlagen, in denen eine Exposition gegenüber ätzenden Stoffen üblich ist.

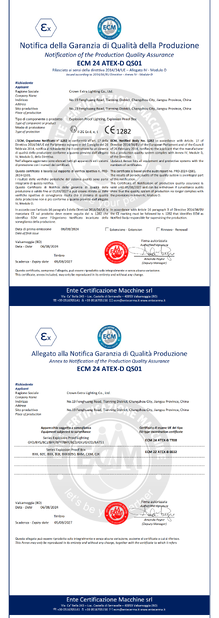

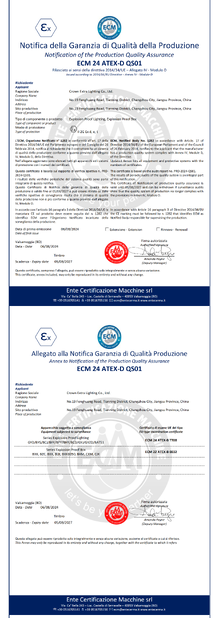

Sicherheit und Einhaltung der Vorschriften sind bei elektrischen Anlagen in gefährlichen Gebieten von größter Bedeutung, und die Ex Proof Cable Gland zeichnet sich in dieser Hinsicht aus.Es verfügt über mehrere international anerkannte ZertifikateDiese Zertifizierungen belegen die Einhaltung strenger Qualitätsmanagementsysteme, Umweltstandards und Sicherheitsvorschriften.Durch die Auswahl dieser Kabeldrüse, stellen Sie sicher, dass Ihre Anlagen den weltweiten Standards entsprechen, wodurch das Unfallrisiko verringert und die allgemeine Sicherheit verbessert wird.

Als flammbeständige Kabeldrüse ist die Ex-Proof-Kabeldrüse so ausgelegt, dass sie alle im Gehäuse auftretenden Funken oder Flammen abhält.Verhinderung der Entflammung der umgebenden explosionsfähigen AtmosphäreDiese entscheidende Eigenschaft macht sie in Umgebungen, in denen brennbare Gase, Dämpfe oder Staub vorhanden sind, unverzichtbar.Das Explosionsrisiko ist minimiert., der sowohl Personal als auch Ausrüstung schützt.

Neben der Explosionssicherheit und der Flammbeständigkeit ist sie durch ihre wasserdichte Dichtung eine vielseitige und wesentliche Komponente für Außen- und Innenanwendungen.Ob Sie mit schweren Maschinen zu tun habenDie wasserdichte Kabeldrüse sorgt dafür, dass Ihre elektrischen Verbindungen sicher und trocken bleiben.Aufrechterhaltung der Betriebseffizienz und Senkung der Wartungskosten.

Zusammenfassend lässt sich sagen, dass die Ex Proof Cable Gland eine Kombination aus robusten Messing- und Gummi-Materialien, einem praktischen Kabeldurchmesser von 6-12 mm (für Kabel von 10-14 mm geeignet)und eine korrosionsbeständige Silberfinish, um ein Produkt zu liefern, das sowohl langlebig als auch zuverlässig istEs ist nach den Normen CE, ROHS und ISO9001 zertifiziert und bietet einen außergewöhnlichen Schutz als wasserdichte Kabeldrüse, flammdichte Kabeldrüse und explosionssichere Kabeldrüse.Dies macht es zur perfekten Wahl für jede gefährliche Umgebung, die höchste Sicherheitsniveaus erfordert., Leistung und Compliance.

Eigenschaften:

- Produktbezeichnung: Ex-Proof Cable Gland

- ATEX/IECEx Kabeldrüsen für gefährliche Umgebungen

- Gefährliche Lage Kabeldrüse zur Gewährleistung der Sicherheit in explosionsgefährdeten Umgebungen

- Glatte Oberfläche für einfache Installation und Handhabung

- Hergestellt aus hochwertigen Messing- und Kautschukmaterialien

- Eintrittsschutz von IP65 und hervorragende Staub- und Wasserbeständigkeit

- Zertifiziert nach CE, ROHS und ISO9001

- Klemmbereich: 6-12 mm, für verschiedene Kabelgrößen

Technische Parameter:

| Klemmbereich |

6 bis 12 mm |

| Geeigneter Kabeldurchmesser |

10 bis 14 mm |

| Typ der Rüstung |

Eindraht-Rüstung |

| Farbe |

Silber |

| Kabeldurchmesserbereich |

6 bis 12 mm |

| Ex Marke |

Ex Db Eb IIC T6 Gb, Ex Tb IIIC T80 °C Db |

| Temperaturbereich |

-20°C bis 80°C |

| Stranglänge |

8 mm |

| Gewinde-Standard |

ISO-Metrik |

| Betriebstemperatur |

-40 ~ +100 Grad |

Anwendungen:

I. Erdöl-, Chemie- und Erdgasindustrie

Erdölgewinnung und -raffinierung: Bohrplattformen, Ölfelder, Raffinerien, Tankstellen, Ölpumpenstationen usw.Diese Standorte sind mit brennbaren und explosionsfähigen Stoffen wie Rohöl gefüllt, Erdgas, Benzin, Diesel und Schwefelwasserstoff.

Chemische Produktion: Chemische Anlagen, Pflanzenschutzmittelanlagen, Düngemittelanlagen, pharmazeutische Anlagen, Farbenanlagen, Harz-Anlagen usw.Bei der Herstellung entstehen große Mengen an brennbaren und explosionsfähigen chemischen Gasen und Staub, Verarbeitung, Lagerung und Transport.

Erdgas: Erdgasverarbeitungsbetriebe, Zulieferstationen für komprimiertes Erdgas (CNG) und Flüssiggas (LNG), Gasleitungsventilkammern usw.

II. Textil- und Holzverarbeitungsindustrie

Textilfabriken: Bei der Verarbeitung von Baumwolle, Leinen, Wolle und anderen Fasern entstehen große Mengen brennbarer Faserflüssigkeit und Staub.

Holzverarbeitung: Sägemühle, Möbelfabriken, Papierfabriken usw. erzeugen brennbaren Holzstaub.

III. Militärische und Luft- und Raumfahrtindustrie

Produktions-, Lager- und Teststandorte für Schießpulver, Sprengstoffe und Munition.

Luft- und Raumfahrt: Tankstellen, Flugzeughangare (in denen sich während der Wartung Treibstoffdampf ansammeln kann), Werkstätten für die Produktion von Raketentriebstoffen usw.

IV. Getreide- und Lebensmittelindustrie

Getreideverarbeitung: Mehlmühlen, Zuckermühlen, Stärkefabriken, Futtermittelverarbeitungsbetriebe, Getreidesilos usw.und Stärke) eine bestimmte Konzentration erreicht., kann es bei Begegnung mit einer Zündquelle zu einer heftigen Staubexplosion führen.

Lebensmittelverarbeitung: Werkstätten für die Herstellung von Speiseöl, Werkstätten für das Brauen von Alkohol usw.

Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten!

Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten! Bitte überprüfen Sie Ihre E-Mail!

Bitte überprüfen Sie Ihre E-Mail!  Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten!

Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten! Bitte überprüfen Sie Ihre E-Mail!

Bitte überprüfen Sie Ihre E-Mail!