Beschreibung des Produkts:

Der Explosionsschalter ist ein hochwertiges elektrisches Bauteil, das in gefährlichen Umgebungen sicher und zuverlässig funktioniert.Kompatibel mit Kabeln mit einem Durchmesser von 9 mm bis 14 mm, erfüllt es die Anforderungen verschiedener industrieller Anwendungen, bei denen eine sichere elektrische Anbindung unerlässlich ist.

Der Schalter ist mit einem robusten Aluminiumgehäuse aus Druckguss gefertigt und bietet eine außergewöhnliche Widerstandsfähigkeit gegen physikalische Schläge und gewährleistet eine langfristige Funktionalität unter schwierigen Bedingungen.Seine robuste Ausstattung macht ihn für den Einsatz in den gefährlichen Gebieten der Zone 1 und Zone 2 geeignet, wo explosionsfähige Atmosphären auftreten können.

Der Schalter verfügt über eine feuerdichte Zertifizierung WF1 und bietet eine überlegene Feuerbeständigkeit, was ihn für sicherheitskritische Anwendungen ideal macht.seine staubdichten Eigenschaften verbessern die Haltbarkeit und ermöglichen einen gleichbleibenden Betrieb auch in staubigen Umgebungen.

für die Steuerung von explosionssicheren Ausfahrtlichtern, Überwachung von Alarmsignalen oder Aktivierung von NotbeleuchtungssystemenDieser Schalter bietet eine sichere und zuverlässige Lösung für verschiedene elektrische SteuerungsanforderungenDas vielseitige Design und die hochwertige Konstruktion machen es zu einem wesentlichen Bauteil in industriellen Umgebungen, in denen Betriebssicherheit und Zuverlässigkeit oberste Priorität haben.

Eigenschaften:

- Produktbezeichnung: Explosionssicherer Schalter

- Kabelspezifikationen: 9 mm-14 mm

- Nennspannung: 220 VAC, 380 VAC

- IP-Klasse: IP54

- Staubdicht: Ja

- Feuerdichte Klasse: WF1

Technische Parameter:

| Produktkategorie | Explosionssicherer Schalter |

| Montageart | Oberflächenbefestigung |

| Typ | Explosionssicherer Schalter |

| Betrieb | Manueller Schalter, kein Aufwärmen erforderlich |

| Außen | Edelstahl |

| IP-Klasse | IP54 |

| Produktbezeichnung | Explosionssichere Wandmontage BHZ51 Schalter für gefährliche Bereiche |

| Ex Markierung | Ex Db IIC T6 Gb,Ex Tb IIIC T80 °C Db |

| Anwendung | Gefährliche Gebiete, Öl- und Gasindustrie |

| Zahl der Polen | 3 |

Anwendungen:

1. Tankstellen - Während des Betankungs- und Entladungsprozesses kann Benzin leicht verdunsten und brennbare Dämpfe bilden. Diese Dämpfe können bei Mischung mit Luft und Exposition gegenüber Funken explodieren.

2. Reaktionsräume chemischer Anlagen - Während des Produktionsprozesses können aus Rohren und Ventilen brennbare und explosionsfähige Gase oder Lösungsdampf wie Benzol, Alkohole und Äther austreten.

3. Kohlebergbautennele - Kohleabläufe emittieren kontinuierlich Methan (Gas) und die Bergbaubetriebe erzeugen große Mengen brennbaren Kohlestaub, was zu einer typischen explosionsfähigen Umgebung führt.

4. Mahlräume für Mehlmühlen - Die Getreideverarbeitung erzeugt Luftpulver, das bei einer bestimmten Konzentration eine Staubexplosion verursachen kann, wenn es einer Zündquelle ausgesetzt ist.

5. Farbsprühkabinen für Fahrzeuge - Farbnebel und Lösungsmitteldämpfe, die durch Verdünner (z. B. Verdünner) während des Sprühens emittiert werden, sind sowohl brennbar als auch explosionsgefährdet.

6. Gaskesselräume/Druckregelstationen - Erdgas (vor allem Methan) -Leitung und -ventile können Leckagen verursachen, und die Ansammlung kann eine explosionsfähige Atmosphäre erzeugen.

7. Alkohol/Literie-Flaschenanlage - Alkohol (Ethanol) ist sehr flüchtig. In einem engen Raum kann sein Dampf bei Mischung mit Luft eine explosive Mischung bilden.

8. Aluminum/Magnesium Alloy Grinding and Polishing Plant - Aluminum and magnesium powders generated during processing are flammable metal dusts that can explode violently when exposed to open flames or high temperatures in air.

9. Anaerobe Tanks in Kläranlagen - Im Klärprozess entsteht als Nebenprodukt Methan (vor allem Methan), das sich leicht in Tanks oder Pumpstationen ansammeln kann.

10- Lösungsmittel-/Farbenlager - Feuerfähige Flüssigkeiten (z. B. Toluol), die an zentralen Standorten gelagert sind, verdunsten kontinuierlich,und die Dampfkonzentration kann ohne ausreichende Belüftung leicht Explosionsgrenzwerte erreichen..

Die Bedeutung der Verwendung von explosionssicheren Produkten:

Explosionssichere Produkte (z. B. explosionssichere Lampen, explosionssichere Steuerungen und explosionssichere Kabel) sind Kerngeräte zur Gewährleistung der industriellen Sicherheit.Dies gilt insbesondere für risikoreiche Industriezweige wie die Erdölindustrie.Die wichtigsten Aspekte sind:

1- Explosionsverhütung und Sicherheit des Personals

Brand- und Explosionsgefährdete Umgebungen: Öl, Erdgas und Staub können leicht zu Explosionen führen, wenn sie Funken oder hohen Temperaturen ausgesetzt sind.

Die Funktion von explosionssicheren Produkten: Durch spezielle Konstruktionen (z. B. flammdichte Gehäuse und intrinsisch sichere Schaltkreise)sie verhindern, dass sich durch innere Funken oder hohe Temperaturen gefährliche Gase/Staub entflammen.

Verringerung von Unfällen: Verhinderung von Verletzungen und Todesfällen von Arbeitnehmern durch Explosionen und Einhaltung der Arbeitsschutzbestimmungen (wie OSHA und GB 3836).

Fallstudie: Eine chemische Fabrik verfehlte die Verwendung einer explosionssicheren Beleuchtung, was zu einer Methan-Explosion führte, die durch einen Kurzschluss bei herkömmlicher Beleuchtung verursacht wurde, was zu erheblichen Opfern führte.

2. Schutz kritischer Ausrüstung und Minimierung wirtschaftlicher Verluste

Industrieausrüstung ist teuer: Ölplattformen, Raffinerien, Kohlengruben und andere Einrichtungen sind sehr wertvoll, und Explosionen können zu Verlusten von zehn Millionen führen.Verhinderung von durch Funken verursachten Beschädigungen der Anlagen, Bögen oder Überhitzung, die seine Lebensdauer verlängern.

Reduzieren Sie die Gefahr von Produktionsunterbrechungen: Eine Explosion kann dazu führen, dass eine Fabrik monatelang stillsteht und die Lieferkette stört.

Fall: Ein Feuer auf einer Offshore-Bohrplattform, das durch einen defekten, nicht explosionssicheren Motor verursacht wurde, führte zu Reparaturen und Produktionsverlusten in Höhe von Hunderten von Millionen Dollar.

3- Einhaltung internationaler Vorschriften, um rechtliche Risiken zu vermeiden.

Eine strenge globale Regelung:

EU: Die ATEX-Richtlinie (2014/34/EU) verpflichtet den Einsatz von explosionssicheren Geräten in Hochrisikogebieten.

US: NEC (National Electrical Code) 500-506 Zonenklassifizierungen, OSHA-Vorschriften.

China: GB 3836-2010 Explosionssicherheitsstandard, Vorschriften für die Sicherheit von Kohlengruben (AQ-Standard).

Strafen für Verstöße: Unternehmen, die nicht explosionssichere Produkte verwenden, können mit hohen Geldstrafen, Produktionsunterbrechungen und sogar strafrechtlichen Verfolgungen konfrontiert werden.

Fall: Eine chemische Fabrik wurde wegen der Verwendung nicht zertifizierter explosionssicherer Schalter mit einer Geldbuße von 500.000 EUR bestraft und der EU zur Aussetzung des Betriebs verordnet.

Verpackung und Versand:

Produktverpackung:

Der explosionssichere Schalter ist sorgfältig in eine robuste Kartonbox verpackt, um einen sicheren Transport zu gewährleisten.

Versandinformationen:

Sobald Ihre Bestellung abgegeben wurde, verarbeitet unser Team sie schnell und versendet den explosionssicheren Schalter an Ihre angegebene Adresse.Wir arbeiten mit zuverlässigen Spediteuren zusammen, um die rechtzeitige Lieferung Ihres Produkts zu gewährleisten.Sie erhalten eine Tracking-Nummer, um den Status Ihrer Sendung zu überwachen.

Häufige Fragen:

F: Wie heißt der Explosionssicherungsschalter?

A: Der Markenname ist CROWN EXTRA.

F: Wie lautet die Modellnummer des Explosionssicherungsschalters?

A: Die Modellnummer lautet ZXF8030.

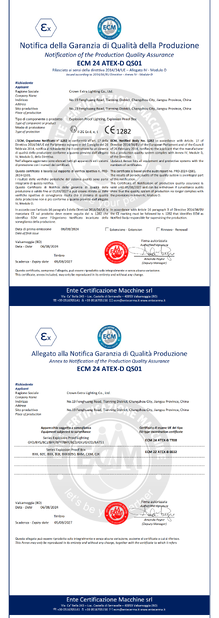

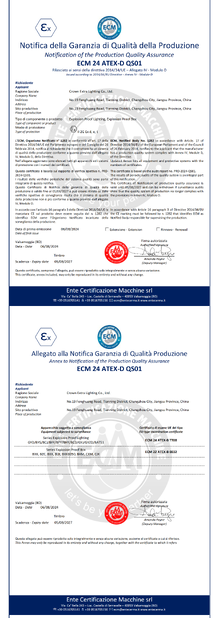

F: Welche Zertifizierungen hat der Explosionssicherungsschalter?

A: Der Explosionsschalter ist mit ATEX, CNEX, ISO und CE zertifiziert.

F: Wie hoch ist die Mindestbestellmenge für den Explosionssicherungsschalter?

A: Die Mindestbestellmenge beträgt 10 Stück.

F: Welche Zahlungsbedingungen werden für den Kauf des Explosionssicherungsschalters akzeptiert?

A: Die akzeptierten Zahlungsbedingungen sind T/T und Western Union.

Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten!

Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten! Bitte überprüfen Sie Ihre E-Mail!

Bitte überprüfen Sie Ihre E-Mail!  Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten!

Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten! Bitte überprüfen Sie Ihre E-Mail!

Bitte überprüfen Sie Ihre E-Mail!